Helping O&G Producers Run Safer, More Efficient

Operations and Maintenance Programs?

As the upstream landscape evolves, producers expect service partners to deliver O&M cost efficiencies through advanced field technologies.

- Home

- Service Providers

The Problem

Two pressures.

One expectation: higher performance

Deepen your value to producers while operating more efficiently and profitably.

Deepen Your Service Value. Capture Digital Demand

As O&G producers accelerate digital and AI adoption, they are redefining how they operate, compete, and deliver long-term shareholder value.

Drive Digital Advantage

Leverage integrated technologies to help producers automate operations and achieve sustainable digital edge.

Balance Cost and Quality

Deliver competitive pricing while maximizing producer efficiency and uptime, without compromising service quality.

Empower Agile Execution

Align with producers’ push for leaner processes and faster delivery by reducing non-value work and accelerating execution.

Operate Your O&M Programs More Efficiently and Profitably

Control costs, optimize your field workforce, and protect margins as you enhance efficiency and resilience across every client project.

Expand High Value Services

Deliver specialized offerings that deepen producer relationships and increase margins.

Optimize Field Productivity

Reduce administrative friction internally and empower your field teams to focus on driving performance.

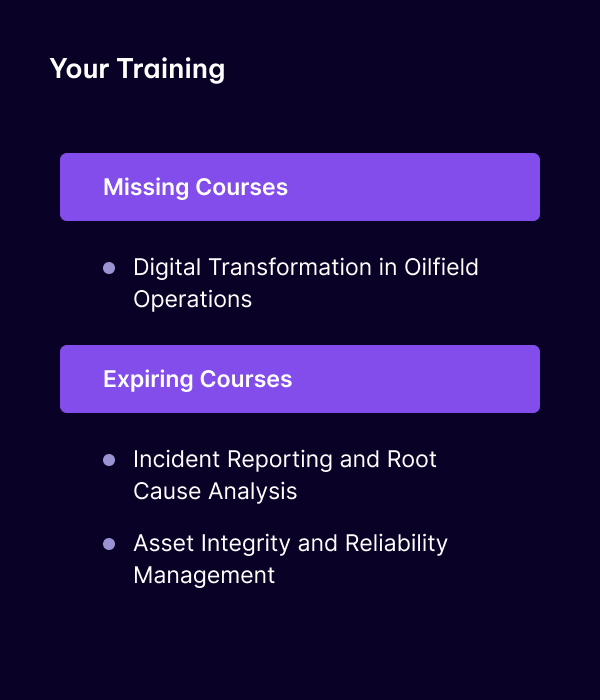

Build an Adaptive Workforce

Equip your people to upskill, adapt, and execute with precision in AI-driven, digitally evolving markets.

The Solution

Transform the last mile of field performance

for your clients and your bottom line

Win more business with a single platform that automates workflows, connecting field operations and corporate support across the industry’s leading O&M programs.

Connected Operations

Bridge the gap between people, processes, and data to create seamless collaboration and consistent results across office and field operations.

Smooth Execution

Eliminate repetitive admin work and disconnected systems that slow progress, enabling faster, smoother, and more efficient field delivery.

Focused Teams

Free field teams from manual tasks and data searches so they can focus on specialized, high-value work that drives real results.

Strategic Advantage

Deliver greater efficiency and visibility to strengthen client relationships, improve outcomes, and expand long-term profitability.

Process Automation

Leverage intelligent automation to streamline complex workflows while ensuring full transparency and consistency across every stage.

Sustainable Growth

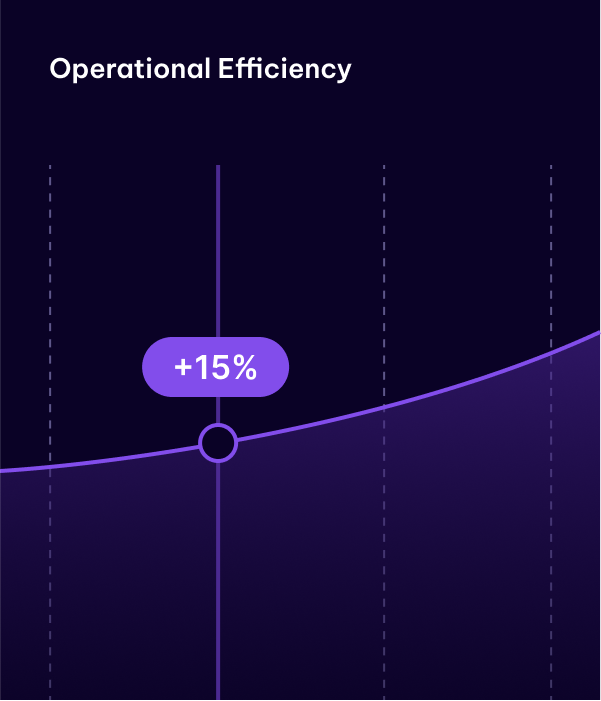

Turn saved hours into measurable gains boosting efficiency, expanding service capacity, and driving scalable, lasting performance.

Deploy Automation

Automate the last mile

of digital transformation

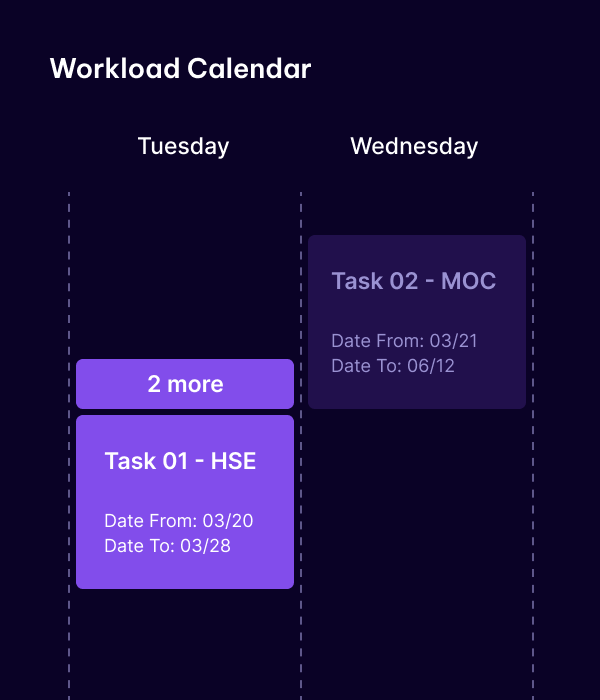

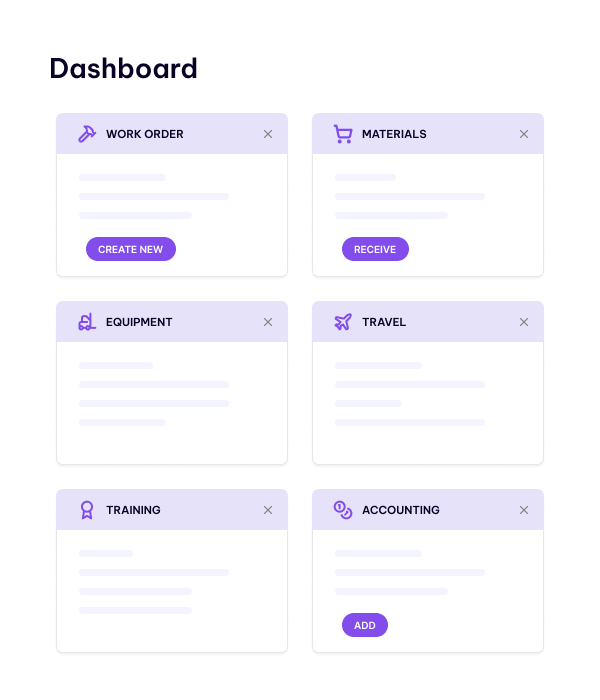

Once work is planned and assigned to field technicians for completion, TRUApp provides O&G producers with one unified platform to manage all three stages of field execution.

-

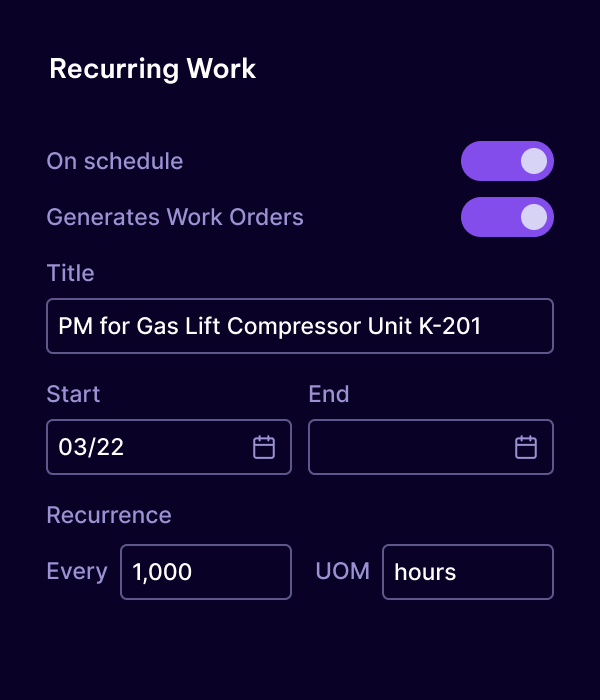

Before Execution Categorize, prioritize, and approve field tasks to set the foundation for efficient, organized execution.

-

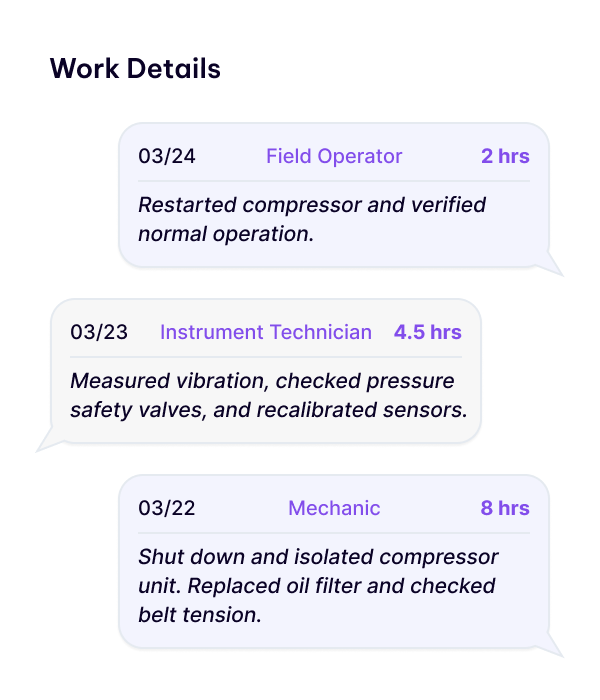

During Execution Track, document, and manage work in real time, ensuring quality is verified and confirmed before completion.

-

After Execution Close out confirmed field tasks, manage post-closure actions, record adjustments, and calculate associated labor and material costs for accounting.

Elevate Performance

Operationalize field

execution workflows

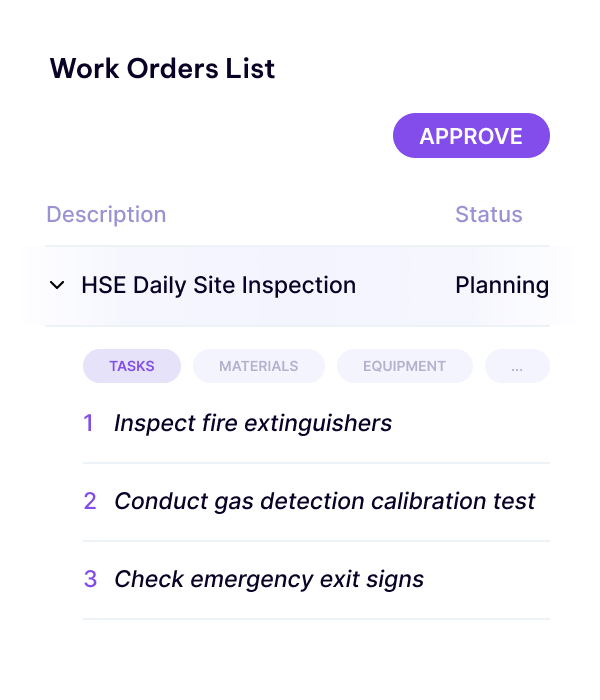

TRUApp empowers your crew to simplify their digital efforts, transforming everyday field activity into a seamless, connected process across the organization.

-

Standardized Workflows in One Location Field teams can now capture, update, and access records and documentation consistently within their daily operations.

-

Eliminated Inefficiencies Less time chasing approvals or searching for materials, documentation, and training. Information is instantly accessible in one place, tailored to each user’s role and access rights.

-

Automated Access TRUApp delivers the right information to the right people at the right time, directly within their personal workflows.

Empower Execution

Connect people, data,

and field execution

TRUApp unites every aspect of field execution and gives teams real-time visibility, actionable data, and the clarity to act on what matters most.

-

Intelligent Data Flow Structured data entered once, automatically organized, and instantly available for analysis and collaboration.

-

Aligned Operations Seamless coordination of work, communication, and visibility provides clear insight into performance, costs, and safety.

-

Actionable Context Understanding of what’s happening now, what comes next, and how every action impacts overall field performance.

Amplify Results

Unlock dormant

organizational gains

TRUApp turns complexity into clarity by connecting all field execution workflows and business processes to drive efficiency, speed, and growth.

-

Unified Field Hub One platform replaces hundreds of scattered shadow systems that support work execution, enabling a standardized and repeatable approach across O&M field teams and activities.

-

Capital Efficiency Streamlined execution drives faster, more flexible, and more effective allocation of capital resources across operations.

-

Sustainable Growth Efficiency gains transform into performance improvements that fuel progress toward energy and production goals.

FAQs

Questions? We've got answers

Browse through our frequently asked questions to find answers regarding TRUApp Energy.

Standardized digital work packets, automated checkpoints, and location and time-stamped evidence deliver verifiable OPEX and HSE gains your producer clients can see in shared dashboards and scorecards. Consistent execution across crews and subcontractors becomes a clear differentiator in bids and renewals, enabling performance-based pricing and savings guarantees. Faster, cleaner closeouts with three-way match and fewer disputes accelerate approvals and cash flow. A repeatable rollout playbook allows you to start with one asset and scale programmatically across the client portfolio.

- Competitive win rate ↑

- Renewal/share-of-wallet ↑

- Dispute cycle time ↓

- Documented savings in bids ↑

Operator-specific permits, stipulations, and approvals are embedded in the job flows rather than chased in emails, spreadsheets, binders, and filing cabinets. Prerequisites are automatically checked before start, PTW/JSA/LOTO steps are system-enforced during execution, and location and time-stamped evidence with role-based approvals builds an immutable audit bundle at closeout. The result is fewer findings and less rework, faster producer approvals, lower claim exposure, and a compliance record your client can trust on a daily basis.

- First-time-compliant jobs ↑

- Audit findings/NCRs ↓

- Permit and closeout cycle time ↓

- Dispute/claim rate ↓

Safety becomes system-enforced. PTW, JSA, and LOTO function as embedded gates with in-flow verifications and barrier checks, and any deviations trigger immediate escalation or auto-hold. Crews capture geo, time, and user-stamped photo and video evidence, creating an immutable record that narrows dispute windows and speeds investigations. Because primes and subcontractors operate within the same digital execution workflows, controls are applied consistently and work drift is detected early. The result is fewer incidents, cleaner closeouts, a stronger claims posture, and a TRIR and insurability profile your producer clients value.

- TRIR ↓

- Time-to-intervene ↓

- Safety deviations/NCRs ↓

- Claim dispute cycle time ↓

- Evidence completeness ↑

Yes. Subcontractors receive role-based, scope-limited access to the same digital work packets, checkpoints, and evidence flow you use, so controls extend to them without additional fragmented tools. You gain like-for-like performance visibility across vendors, including readiness, deviations, rework, and utilization. Non-conformances route immediately according to your standards, and time and materials remain synchronized for faster and cleaner closeouts. Data and audit trails stay under your control, while subcontractors operate efficiently under the same rules and with the same records.

- Sub onboarding time ↓

- Non-conformance rate ↓

- Verified vendor utilization ↑

- Closeout cycle time ↓

Supervisors view a live, constraint-aware board on mobile with permit, materials, and LOTO readiness, along with crew availability, skills, asset status, and standardized delay reasons, all tied to each work packet. The system flags exceptions, recommends next best assignments, and allows foremen to re-sequence work with a few clicks, with automatic notifications sent to crews and subcontractors. The result is fewer idle gaps, cleaner handoffs, higher daily completions, and stronger schedule adherence without chasing updates across spreadsheets, databases, apps, emails, or texts.

- Decision latency ↓

- Daily completion rate ↑

- Schedule variance ↓

- Idle time ↓

Yes. Closeout packets auto-assemble PTW, JSA, LOTO, photos, meter readings, materials, and as-builts, while time and materials are captured once at the point of work and coded to work orders, purchase orders, and cost centers. Exceptions are flagged in flow, and a three-way match runs before invoice creation. Producer-ready reports are generated automatically, and custom feeds push clean data to ERP and Payroll, reducing reconciliations, resubmissions, and email chases. The result is lower overhead per job and faster approvals without adding tools or headcount.

- Back-office hours per job ↓

- Exception-free invoices ↑

- Reconciliation cycle time ↓

Margin expands on three fronts: cost, cash, and commercials. On cost, one platform drives first-time-right execution with less rework and standby, higher crew and equipment utilization, and leaner closeouts, which reduces overhead per job.

On cash, verified time and materials and automated three-way match cut disputes and speed approvals, which shortens DSO and reduces leakage.

On commercial terms, standardized, producer-aligned performance data allows you to bid and renew with evidence-based savings, supporting performance-based pricing and bonus structures. As adoption scales across primes, subcontractors, and assets, network effects take hold within the app. The same rules and the same records apply everywhere, so gains compound at the portfolio level.

- Gross margin ↑

- Crew utilization ↑

- Rework % ↓

- Disputed invoices ↓

- Back-office hours per job ↓

Yes. Predictable, evidence-based field execution lifts crew and equipment utilization, reduces schedule slippage, and standardizes unit costs across assets so your client can shrink contingencies and reallocate OPEX with confidence. Verified time and materials and three-way match reduce leakage and working-capital drag, while portfolio dashboards demonstrate backlog throughput and uptime gains. You do more than deliver tasks; you de-risk the asset plan and position your firm as a strategic partner rather than a commodity contractor.

- Schedule variance ↓

- OPEX per BOE ↓

- Backlog burn-down ↑

- Exception-free invoices ↑

- Working-capital days ↓

- Contingency % ↓

Invoices are built from verified field records, with time and materials captured once and location, time, and user-stamped, then priced against the contracted rate card and run through automated three-way match. Line-item variances are resolved with supporting evidence attached, and approved change orders are captured within the execution workflows, not after the fact. Producer-ready packets aligned to preferred submission standards reduce back-and-forth, shorten approvals, and cut write-offs, so cash is positioned to land faster and with fewer surprises.

- First-pass acceptance ↑

- Disputed invoices ↓

- Write-offs/credits ↓*

The platform generates a clean, standardized field dataset that includes scope, problems, time, materials, conditions, and outcomes tied to WO, PO, and precise location, time, and user stamps. Out of the box, you gain risk and duration forecasts, crew and equipment optimization, anomaly flags for time and materials leakage, and leading indicators of HSE drift that you can apply in bids, planning, and daily dispatch. You can export data to your own models or use built-in analytics, with strict client-level partitioning and governed lineage that supports audit requirements. The result is better bids, tighter execution, and continuous improvement without building a data stack from scratch.

- Forecast accuracy ↑

- Productivity per crew ↑

- Cost and schedule variance ↓

- Bid win rate ↑

Launch Quickly. With Confidence.

Transform field execution.

Empower performance.

Automate workflows across all three phases of execution and connect field teams along the last mile of O&G performance to deliver breakthrough results.

Get started now

Give us a call at 888-7-TRUApp (888.787.8277) or fill in the form below and our team will get back to you shortly.