Facilities, Pipelines, and Personnel?

Eliminate tens of thousands of hours of low-value administrative work per asset each year. Reduce OPEX and free field specialists to focus on high-value O&M activities that drive strategic performance and increase shareholder value.

- Home

- Producers

Purpose-Built for OG&E

Automate where performance and cost converge along the last mile of field execution

Digital Enterprise Execution Performance Management (DEEP-M™) empowers clients to digitize, orchestrate, and enable field specialists through the final stages of operational execution.

TRUApp starts where enterprise planning ends, at the point where field-level planning, systems, and people intersect to get the work done safely and cost-effectively.

- Powerful solution

- Rapid implementation

The Problem

Disconnected systems erode productivity

and inflate field operating costs

Redundant data entry and inefficient searches for materials, documentation, and approvals generate hundreds of hours of lost productivity across the field and back office each day.

Field Technician

No field technician likes to do low-value, administrative, manual data work or spend hours searching across disconnected systems for the information they need just to do their job, when they could be focused on what really moves the work forward.

“Why do I have to jump between so many systems just to find what I need and document my work? If it were all in one place, we’d save so much time and frustration.”

Department Leader

No department leader wants their field technicians spending hours each day on busywork and chasing down information that has already been entered into another system, when they could be focusing on the strategic work they’ve prioritized.

“I don’t want the field re-entering data all day – I want them focused on the specialized work they were trained to do. All this manual effort just slows everyone down.”

Office Executive

No office executive wants hours upon hours of non-productive labor time to accumulate unnoticed each day across all the field assets in their portfolio, when that time could be redirected toward driving efficiency, performance, and measurable results.

“Why are field and back-office teams juggling so many systems, spreadsheets, and databases just to do their work? How much time are we losing every single day across all assets?”

The Solution

Discover the simplicity

of TRUApp Energy

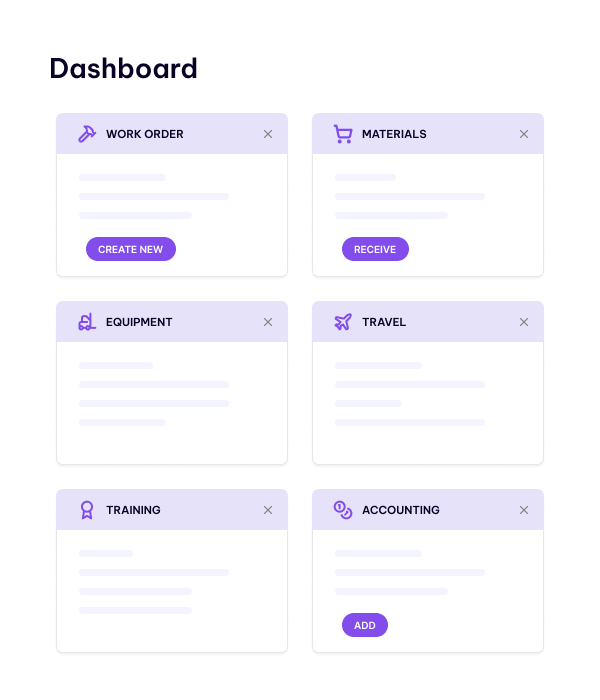

Explore the key features that turn complex field workflows and business processes into streamlined execution, measurable efficiency, and real results.

Operational Flow

Close performance gaps with technology that eliminates time lost to admin work and information searches.

Time Savings

Free up tens of thousands of hours annually for field experts to focus on high-value, strategic work.

Performance Clarity

Streamline complex, costly execution processes and improve visibility across every phase of delivery.

Unified Input

Enable every employee to record work details once, in one place, regardless of role or location.

Smart Automation

Let TRUApp handle routine workflows automatically while maintaining enterprise transparency and control.

Compliance Assurance

Ensure every task, record, and workflow aligns with operational, safety, and regulatory standards.

Deploy Automation

Automate the last mile

of digital transformation

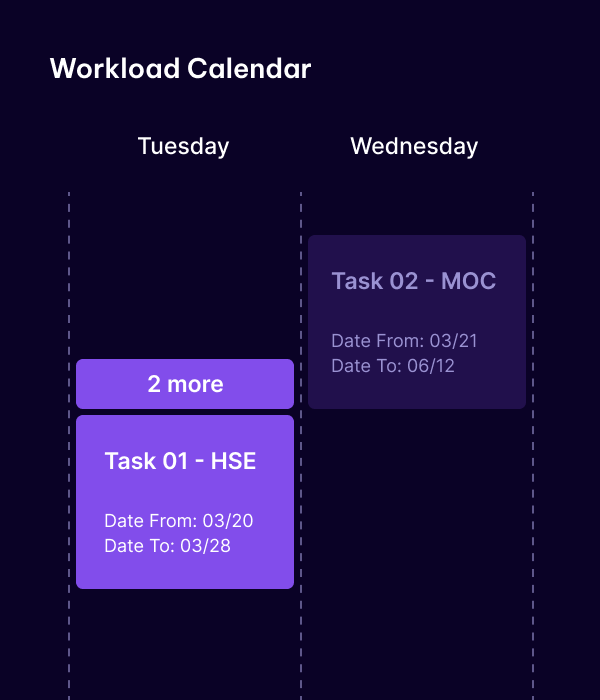

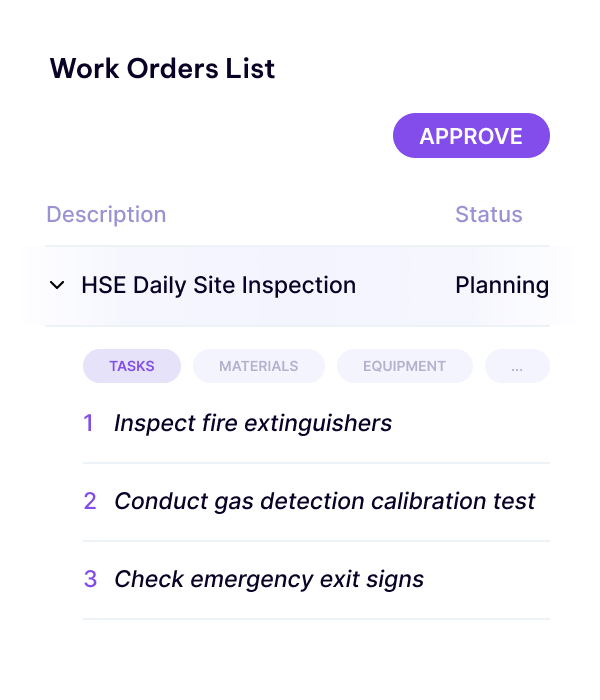

Once work is planned and assigned to field technicians for completion, TRUApp provides O&G producers with one unified platform to manage all three stages of field execution.

-

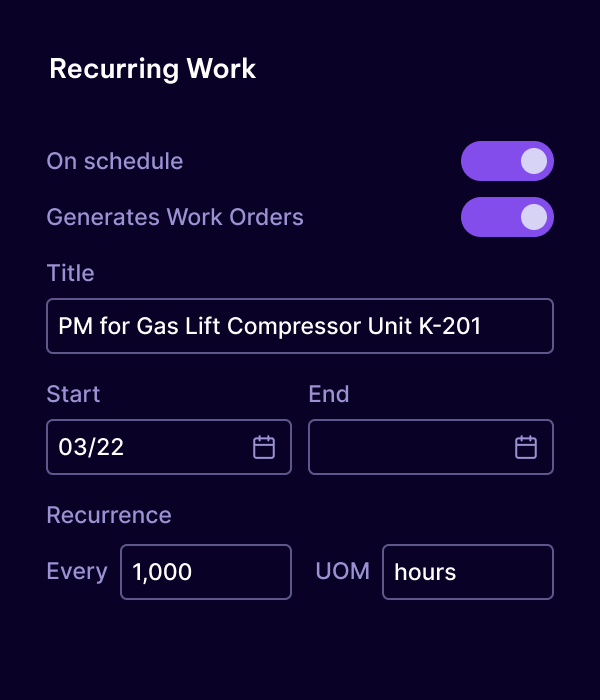

Before Execution Categorize, prioritize, and approve field tasks to set the foundation for efficient, organized execution.

-

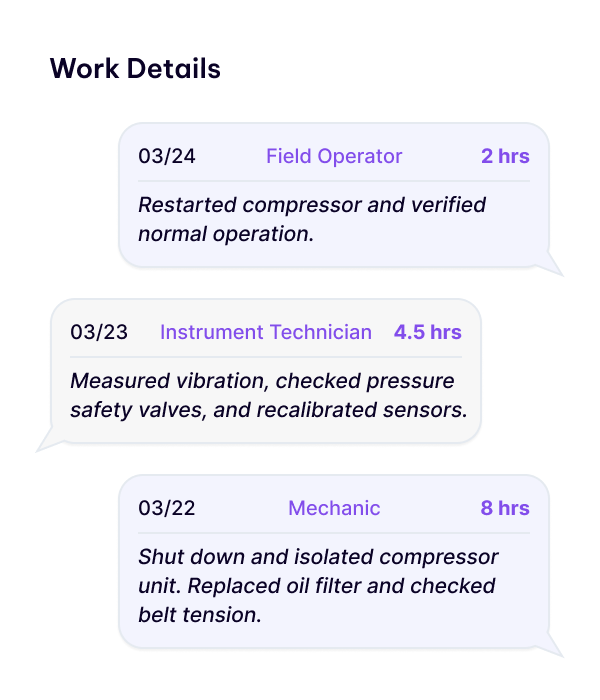

During Execution Track, document, and manage work in real time, ensuring quality is verified and confirmed before completion.

-

After Execution Close out confirmed field tasks, manage post-closure actions, record adjustments, and calculate associated labor and material costs for accounting.

Elevate Performance

Operationalize field

execution workflows

TRUApp empowers your crew to simplify their digital efforts, transforming everyday field activity into a seamless, connected process across the organization.

-

Standardized Workflows in One Location Field teams can now capture, update, and access records and documentation consistently within their daily operations.

-

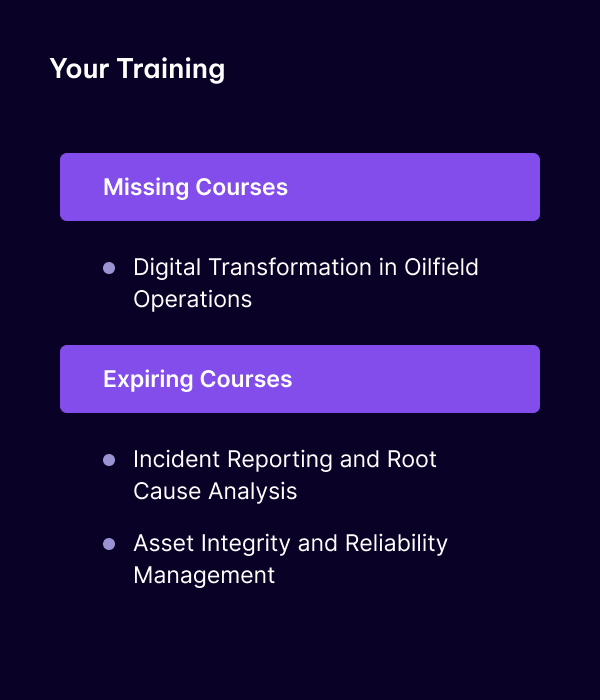

Eliminated Inefficiencies Less time chasing approvals or searching for materials, documentation, and training. Information is instantly accessible in one place, tailored to each user’s role and access rights.

-

Automated Access TRUApp delivers the right information to the right people at the right time, directly within their personal workflows.

Empower Execution

Connect people, data,

and field execution

TRUApp unites every aspect of field execution and gives teams real-time visibility, actionable data, and the clarity to act on what matters most.

-

Intelligent Data Flow Structured data entered once, automatically organized, and instantly available for analysis and collaboration.

-

Aligned Operations Seamless coordination of work, communication, and visibility provides clear insight into performance, costs, and safety.

-

Actionable Context Understanding of what’s happening now, what comes next, and how every action impacts overall field performance.

Amplify Results

Unlock dormant

organizational gains

TRUApp turns complexity into clarity by connecting all field execution workflows and business processes to drive efficiency, speed, and growth.

-

Unified Field Hub One platform replaces hundreds of scattered shadow systems that support work execution, enabling a standardized and repeatable approach across O&M field teams and activities.

-

Capital Efficiency Streamlined execution drives faster, more flexible, and more effective allocation of capital resources across operations.

-

Sustainable Growth Efficiency gains transform into performance improvements that fuel progress toward energy and production goals.

FAQs

Questions? We've got answers

Browse through our frequently asked questions to find answers regarding TRUApp Energy.

Because execution is where all this fragmentation compounds risk and cost. Multiple tools mean multiple handoffs, blind spots, and rework. In contrast, one interconnected platform standardizes how field work is planned, performed, and verified across all three stages of execution, uniting teams, positions, locations, and assets. It eliminates duplicate entries, surfaces exceptions in real time, and creates a single, auditable source of truth from the field to the back office.

Operationalizing execution ensures tighter controls, safer production, and materially lower OPEX at portfolio scale.

- OPEX per BOE ↓

- Schedule adherence ↑

- Wrench time ↑

- Exception-free invoices ↑

- HSE deviations ↓

Compliance lives within the details of field execution. Automation that supports controls, permits, and evidence ensures these details are captured as the work happens, preventing gaps and generating a complete, time-stamped audit trail in one location. This applies across all departments, specialists, and sites involved.

Think role-based records spanning the entire execution lifecycle. You are reducing audit exposure and investigation cycle times while improving first-time compliance.

- HSE deviations ↓

- Exceptions detected and resolved in-shift ↑

- First-time-compliant jobs ↑

- Permit turnaround time ↓

- Findings per audit ↓

Safety workflows are unified across field operations because they are system-enforced. Permit to Work (PTW), Job Safety Analysis (JSA), isolations, and barrier checks become embedded steps within the process, not just "paperwork to be completed". With in-flow execution verifications and asset-based time stamps, you secure an immutable record of accountability and compliance.

Rules-based deviations trigger instant escalation through the designated chain of command, reducing both the likelihood and severity of incidents.

- SIF/HIPO events ↓

- TRIR ↓

- Time-to-intervene ↓

- PTW/JSA/LOTO adherence % ↑

- Unplanned HSE-related downtime ↓

All parties execute O&M field work through the same workflow, within the same platform, with standardized work packages, automation driven checkpoints, and digital touchpoints of evidence. You gain complete visibility into who did what, when, and where.

No more email or paper chases – institutional field knowledge is preserved, performance management is strengthened through conformance trend analysis, and timekeeping stays fully aligned.

- Exception-free invoices ↑

- Vendor non-conformance rate ↓

- Verified vendor utilization ↑

- Schedule adherence ↑

Structured data captured at the point of work replaces lagging, manual, and inconsistent reports that need to be assembled from multiple sources. Leaders are empowered to act on live readiness, delays, rework, and outcomes, replacing "opinions about the field" with observable, accessible facts in one location that strengthen timely and confident decision making.

- OPEX per BOE ↓

- Production deferment hours ↓

- Schedule adherence ↑

- Decision latency ↓

- Forecast accuracy ↑

Yes. When field operations personnel can execute O&M work within a single system, spreadsheets and other rogue apps, while often helpful, actually represent single points of potential failure and begin to fade away. IT governance improves because platform automation enforces roles, data standards, and security. The ability to integrate with existing ERP and other enterprise systems is automated through clean execution data.

- OPEX per BOE ↓

- Exception-free invoices ↑

- Data reconciliation hours ↓

- Software TCO ↓

- Audit findings per audit ↓

Profitability gains come from fewer execution-related handoffs and errors, higher wrench time, less rework, and faster closeouts across departments, personnel, locations, and portfolios.

Automation replaces manual, spreadsheet-driven processes, reducing downtime and eliminating unnecessary coordination, consolidation, and correction.

You spend less time and money on low-value administrative capture and more time safely executing high-value, strategic work – all while using less software with less direct and indirect licensing, maintenance, and training costs.

- OPEX per BOE ↓

- Production deferment hours ↓

- Exception-free invoices ↑

- Wrench time ↑

- Rework % ↓

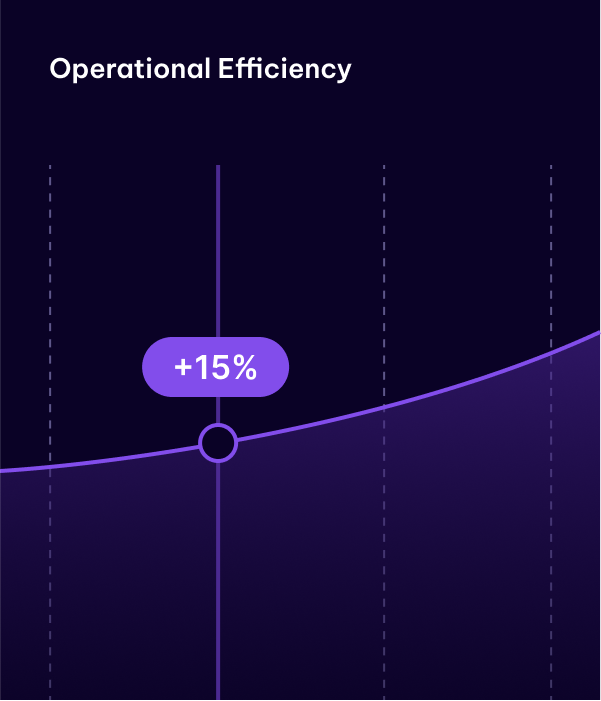

Centralizing the execution of O&M workflows and business processes within a single tool, supported by automation, improves crew and equipment utilization while reducing schedule slippage. These execution gains compound across teams, assets, locations, and portfolios. The resulting operational efficiencies, combined with lower software licensing and training costs, free up OPEX.

Better management and predictability across the three execution phases of field operations de-risk current assets and release capital capacity for your next strategic projects.

- OPEX per BOE ↓

- Schedule variance ↓

- Crew and equipment utilization ↑

- Working capital days ↓

- Contingency % ↓

We spent the last 14 years mapping the interconnected workflows that define oil and gas field operations. The result is an industry-specific ontology of O&M execution that powers the complex coordination and automation embedded within our platform.

This allows us to uniquely deliver producers a consistent, domain-specific dataset of execution details including scope, risks, time, materials, conditions, and outcomes, all captured automatically using a unified taxonomy. Real-time access and reporting are available at the push of a button.

You have already advanced digital transformation across the field. Execution remains the last untapped mile to elevate performance.

- OPEX per BOE ↓

- Schedule variance ↓

- Production deferment hours ↓

- Forecast accuracy ↑

- Decision latency ↓

Launch Quickly. With Confidence.

Transform field execution.

Empower performance.

Automate workflows across all three phases of execution and connect field teams along the last mile of O&G performance to deliver breakthrough results.

Get started now

Give us a call at 888-7-TRUApp (888.787.8277) or fill in the form below and our team will get back to you shortly.