Extend Enterprise Transformation

to the Last Mile of Field Performance

Complement the technology platforms you already work with to deliver exponential value for producers through real-time execution performance management across the field.

- Home

- Global Systems Integrators

Built for Upstream O&G

Together, we can deliver the next generation of operational excellence for the

Oil & Gas industry

Extend enterprise transformation to the field with a platform that bridges planning and execution. Unlock new productivity, cost savings, and reliability gains for your producer clients.

- Smart operations

- Seamless integration

The Problem

The Oil & Gas industry’s largest untapped source

of performance advantage is in the field

Augment producers’ digital and AI transformations by addressing the multi-billion-dollar OPEX inefficiencies hidden within the workflows of disconnected field operations.

In the Field

No Producer wants their field technicians buried in low-value administrative work or spending hours searching through disconnected systems for the information they need just to do their jobs, when that time could be spent on meaningful work.

“Why are we juggling so many systems just to get our work done? If everything were in one place, it would make our jobs faster, easier, and far less frustrating.”

In Operations

No department leader at your Producer clients wants their field teams tied up in repetitive admin work and chasing down data across multiple systems, when they could be focused on high-value tasks that keep production moving forward.

“I don’t want field teams copying, pasting, and re-entering data all day. If this process were automated, everything would move faster and run smoother.”

In the Office

No upstream home office executive wants hours upon hours of non-productive labor time quietly adding up each day across every field asset in their portfolio, when that effort could be focused on improving operational efficiency.

“Why are our personnel working across so many different systems? How much time are we really losing every single day across all our assets as a result?”

The Solution

Unlock years of productivity gains and

deepen capital efficiency for future energy goals

Deliver measurable OPEX reductions that free up capital for producers to advance their long-term energy goals by standardizing how O&M fieldwork is executed across assets worldwide.

Unified Field Solution

Deliver a single platform built to eliminate administrative and transparency bottlenecks across every stage of field execution.

Expanded Capabilities

Enhance your service offerings and strengthen client value through smarter, more connected operational performance.

Digital Partnership

Support Producers’ digital transformation initiatives with modular, low-risk integration that accelerates measurable outcomes.

Revenue Growth

Increase profitability by closing hidden industry gaps and converting operational inefficiencies into lasting performance gains.

Operational Clarity

Simplify the complexity of field execution for both internal teams and upstream clients, driving consistency across every phase of delivery.

Seamless Integration

Automated execution that works with clients' existing enterprise systems, maintaining full transparency between office and field teams.

Deploy Automation

Automate the last mile

of digital transformation

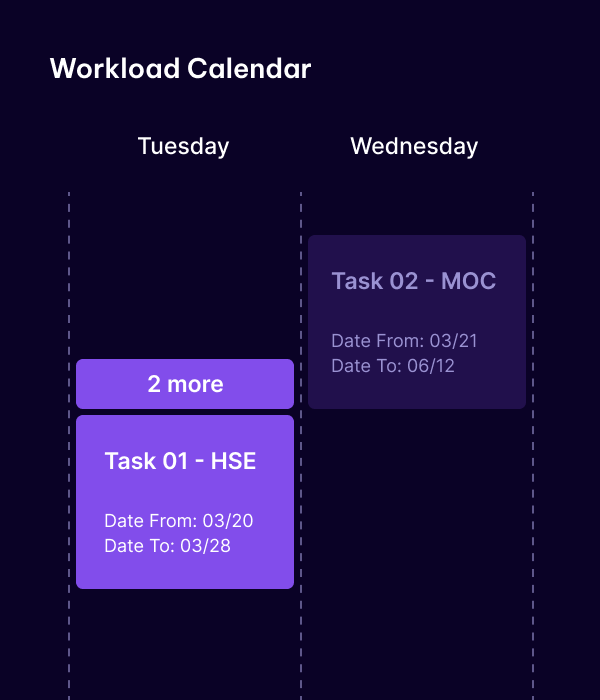

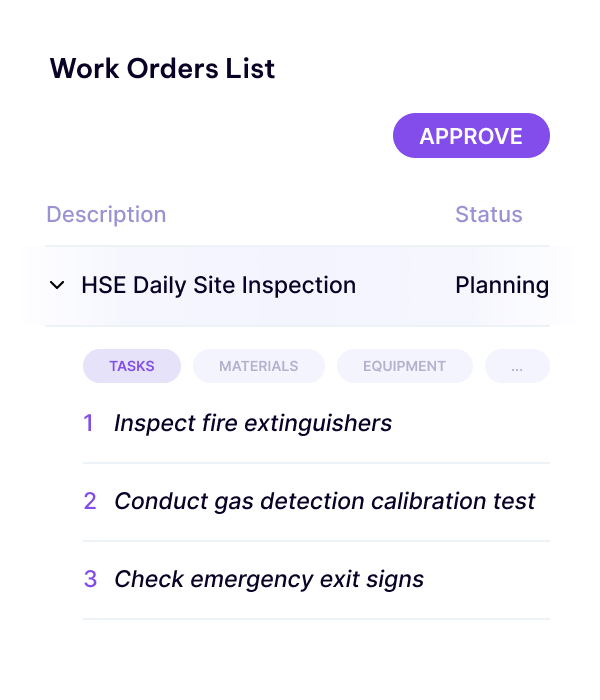

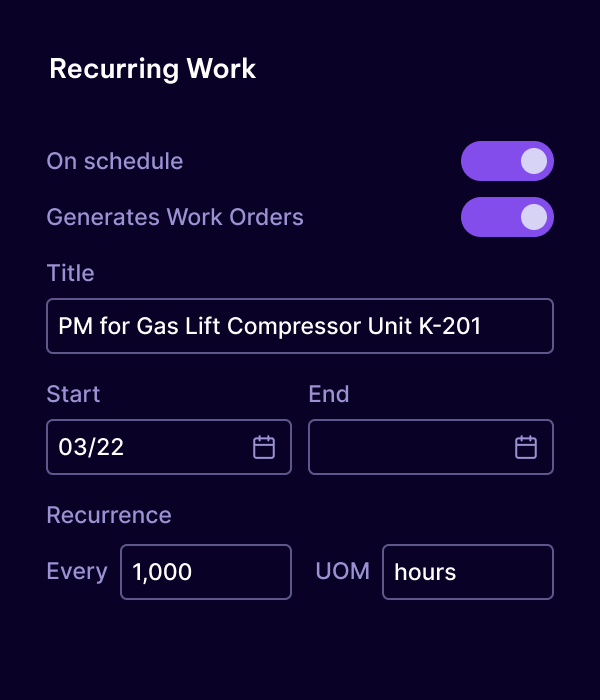

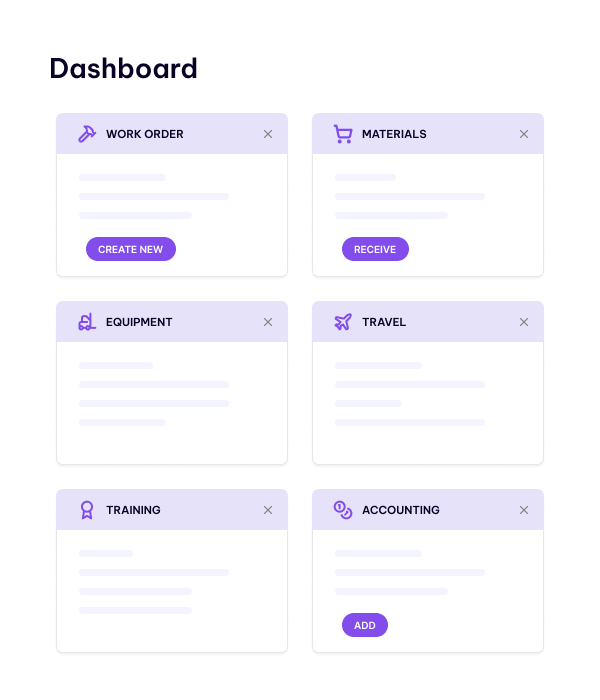

Once work is planned and assigned to field technicians for completion, TRUApp provides O&G producers with one unified platform to manage all three stages of field execution.

-

Before Execution Categorize, prioritize, and approve field tasks to set the foundation for efficient, organized execution.

-

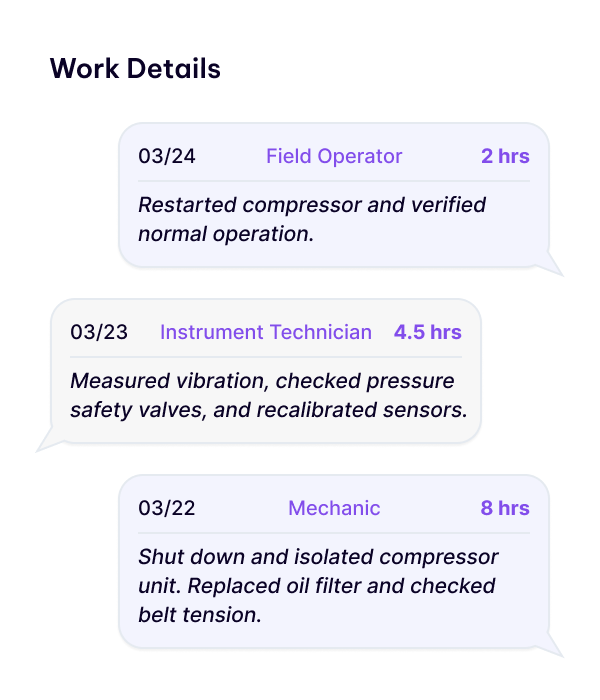

During Execution Track, document, and manage work in real time, ensuring quality is verified and confirmed before completion.

-

After Execution Close out confirmed field tasks, manage post-closure actions, record adjustments, and calculate associated labor and material costs for accounting.

Elevate Performance

Operationalize field

execution workflows

TRUApp empowers your crew to simplify their digital efforts, transforming everyday field activity into a seamless, connected process across the organization.

-

Standardized Workflows in One Location Field teams can now capture, update, and access records and documentation consistently within their daily operations.

-

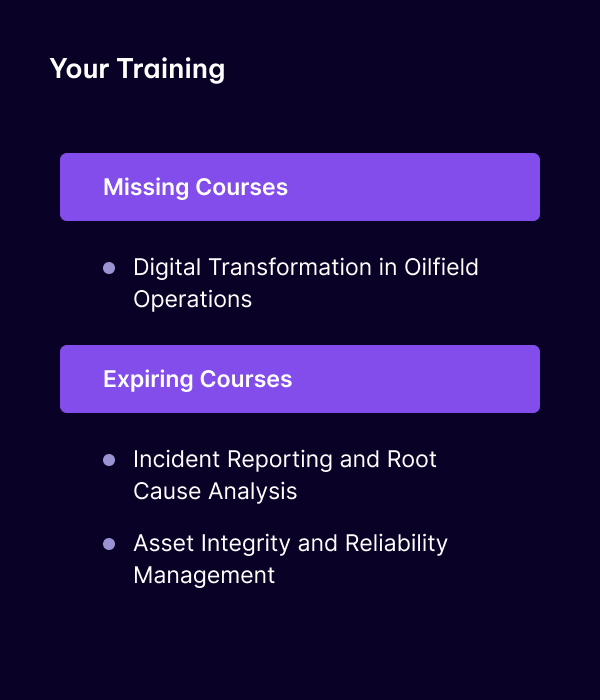

Eliminated Inefficiencies Less time chasing approvals or searching for materials, documentation, and training. Information is instantly accessible in one place, tailored to each user’s role and access rights.

-

Automated Access TRUApp delivers the right information to the right people at the right time, directly within their personal workflows.

Empower Execution

Connect people, data,

and field execution

TRUApp unites every aspect of field execution and gives teams real-time visibility, actionable data, and the clarity to act on what matters most.

-

Intelligent Data Flow Structured data entered once, automatically organized, and instantly available for analysis and collaboration.

-

Aligned Operations Seamless coordination of work, communication, and visibility provides clear insight into performance, costs, and safety.

-

Actionable Context Understanding of what’s happening now, what comes next, and how every action impacts overall field performance.

Amplify Results

Unlock dormant

organizational gains

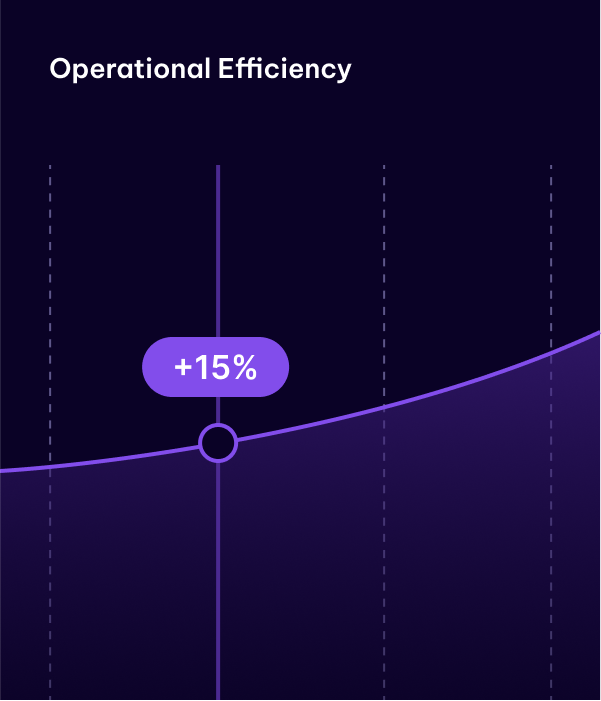

TRUApp turns complexity into clarity by connecting all field execution workflows and business processes to drive efficiency, speed, and growth.

-

Unified Field Hub One platform replaces hundreds of scattered shadow systems that support work execution, enabling a standardized and repeatable approach across O&M field teams and activities.

-

Capital Efficiency Streamlined execution drives faster, more flexible, and more effective allocation of capital resources across operations.

-

Sustainable Growth Efficiency gains transform into performance improvements that fuel progress toward energy and production goals.

FAQs

Questions? We've got answers

Browse through our frequently asked questions to find answers regarding TRUApp Energy.

Standardizing on a single field execution platform turns the largest uncontrolled performance gap in operations, execution at the point of work, into a governed and measurable system of action that you design once and scale everywhere. A global execution blueprint covering before, during, and after, combined with a shared ontology, democratizes access while preserving local nuance.

Event-driven integrations move clean execution data into ERP/modules and enterprise data warehouses with fewer custom builds. Embedded permits, checkpoints, and exception logic drive tangible OPEX and HSE improvements while producing AI-ready data. Role-based user experiences and executive-driven dashboards accelerate adoption and verify results. The outcome is lower delivery risk, faster time-to-value, and durable advisory, build, and run attach across the portfolio.

- Time-to-first-site ↓

- Cost per site ↓

- Adoption ≥90% in 60 days

- Audit findings ↓

- OPEX/BOE ↓

- % sites live per quarter ↑

By standardizing a portfolio-wide control catalog and evidence model, and then parameterizing them for local regulations, you replace ad hoc compliance with a repeatable, audited system of action. Mandatory steps and in-flow verifications generate asset location, time, and user-stamped evidence automatically, while event or time-driven integrations feed ERP, DMS (document management systems), and regulatory reporting without manual collation.

The platform auto-builds audit packets and surfaces portfolio-wide insights on control effectiveness and non-conformances, so you shorten audit cycles, reduce findings, and demonstrate consistency across assets and vendors. You achieve compliance at scale without sacrificing local regulatory nuance.

- First-time-compliant jobs ↑

- Audit cycle time ↓

- Findings per audit ↓

- Evidence completeness ↑

- Time-to-audit-packet ↓

- Exceptions detected and resolved in-shift ↑

Yes. Make HSE governed in the workflow, not after the fact. Embed a standardized, version-controlled control catalog (PTW, JSA, LOTO, isolations, barrier checks) as mandatory gates with in-flow verifications, and trigger real-time escalation or auto-hold on exceptions. Sync roles, certifications, and procedures from HR, LMS, and DMS so only qualified personnel can start work, and give managers instant visibility into training status.

Use portfolio dashboards to reveal control effectiveness and work drift across sites and vendors, and run integrated incident management from reporting to root-cause analysis to corrective actions to verification, with a complete audit trail. The result is earlier intervention, fewer deviations, and consistent HSE performance at enterprise scale.

- TRIR ↓

- Time-to-intervene ↓

- Control deviation rate ↓

- Training compliance % ↑

- Incident close cycle time ↓

- Evidence completeness ↑

By standardizing the field ontology and KPI definitions, then sharing validated, lineage-tracked events from execution at the point of work, your programs replace manual rollups with board-ready and comparable metrics across assets and vendors. A shared semantic layer powers steering dashboards with control limits and automatically drills into job-level evidence, so variance discussions shift from anecdote to auditable facts.

Real-time alerts, benchmarking, and in-workflow decision capture create closed-loop governance, while managed reviews sustain adoption at scale. The result is faster, cleaner decisions and a governance model your clients can extend portfolio-wide.

- Time-to-steering pack ↓

- Metric adoption across sites ↑

- Data completeness and timeliness ≥95%

- Decision latency ↓

- Governance exceptions auto-detected and resolved in-shift ↑

- Variance explained coverage ↑

We design value directly into the execution performance management platform. A finance-approved KPI tree links field execution to the P&L, with baselines and control groups established before rollout. Point-of-work detail capture removes the need for manual rollups. Embedded controls, three-way match, and exception routing lift utilization, reduce rework and standby, and improve invoice quality.

Dashboards present defensible value metrics, with variances fully attributed to specific sites and vendors. Detailed costs and evidence of work are collected at each phase and are ready for audit.

- Time-to-first-value ↓

- OPEX per BOE ↓

- Rework % ↓

- Exception-free invoices ↑

- Adoption ≥ 90% in 60 days

Our approach keeps ERP and point tools as the systems of record and adds a field-built system of action that standardizes the plan – execute – close processes at the point of work. A shared ontology and clear data contracts align process and controls. Event-driven integrations sync master data and return clean execution facts (time, materials, evidence) to ERP, so you avoid rip and replace. Automated closeout, GL coding, and pre-invoice three-way match strengthen financial integrity, while one-click dashboards provide end-to-end transparency from crew readiness to cost drivers.

With role-based UX, adoption is fast, reconciliations shrink, and core platforms receive better data with fewer customizations. The result is lower delivery risk, lower TCO, and a simpler operating model.

- WO completeness and GL coding accuracy ↑

- Reconciliation cycle time ↓

- Custom integration defects ↓

- Exception-free invoices ↑

- Time-to-closeout ↓

- Shadow tools and app count ↓

For Producers, the governance win is retiring shadow tools and redundant tech by moving execution into a single, governed, execution-oriented system of action that preserves ERP and specialty systems as systems of record. With a shared ontology, you gain standardized data, positional access rights supported by immutable audit logs, and continuous controls monitoring, so policy becomes provable evidence at the point of work. Environment segregation, formal change control, and a cataloged data layer reduce integration risk and technical debt, while access management keeps compliance current.

The result is fewer apps to police, stronger security and auditability, and better data quality feeding core platforms, without a rip and replace of operationally disruptive systems.

- Shadow tool count ↓

- Access reviews on time ↑

- Audit finding closure time ↓

- Integration defects ↓

- Master-data conformance ↑

- Time to provision or deprovision ↓

A single field-execution platform converts O&M work into predictable unit costs and durations that scale from asset level to portfolio level. Event and time-oriented integrations send coded, verified facts to ERP, its modules, and the EDW (enterprise data warehouse), including three-way-matched time and materials and in-flow change orders, which cuts leakage and shortens working-capital days. Embedded readiness gates and exception routing raise utilization and reduce rework, which shrinks schedule variance so contingencies can come down and capital can be rephased with confidence.

Asset-level playbooks and dashboards connect backlog throughput and unit-cost trends to cash impacts, enabling producers to free OPEX and fund priority projects. Your program is then able to demonstrate measurable results quarter after quarter.

- Utilization ↑

- Schedule variance ↓

- OPEX per BOE ↓

- Backlog burn-down ↑

- Working-capital days ↓

- Contingency % ↓

- Capital throughput ↑

Sensors tell you what happened, execution data and details explain what happened next by the field technicians, when, why and how. By standardizing a domain-specific field ontology and sharing location, time, and user-stamped events into your feature set, then aligning them with IoT and ERP or specialty systems, you enable trustworthy risk, duration, and cost forecasts. These forecasts then feed workflow decisions such as holds, escalations, and next-best actions.

The closed loop turns analytics into outcomes: fewer incidents, tighter schedules, lower unit costs, and governed lineage with work drift monitoring and execution playbooks that make the value repeatable across assets and vendors.

- Forecast accuracy (MAE/MAPE) ↑

- Schedule variance ↓

- Cost variance ↓

- Time-to-intervene ↓

- Rework % ↓

- Model adoption (users or actions) ↑

Launch Quickly. With Confidence.

Transform field execution.

Empower performance.

Automate workflows across all three phases of execution and connect field teams along the last mile of O&G performance to deliver breakthrough results.

Get started now

Give us a call at 888-7-TRUApp (888.787.8277) or fill in the form below and our team will get back to you shortly.